Headquarters

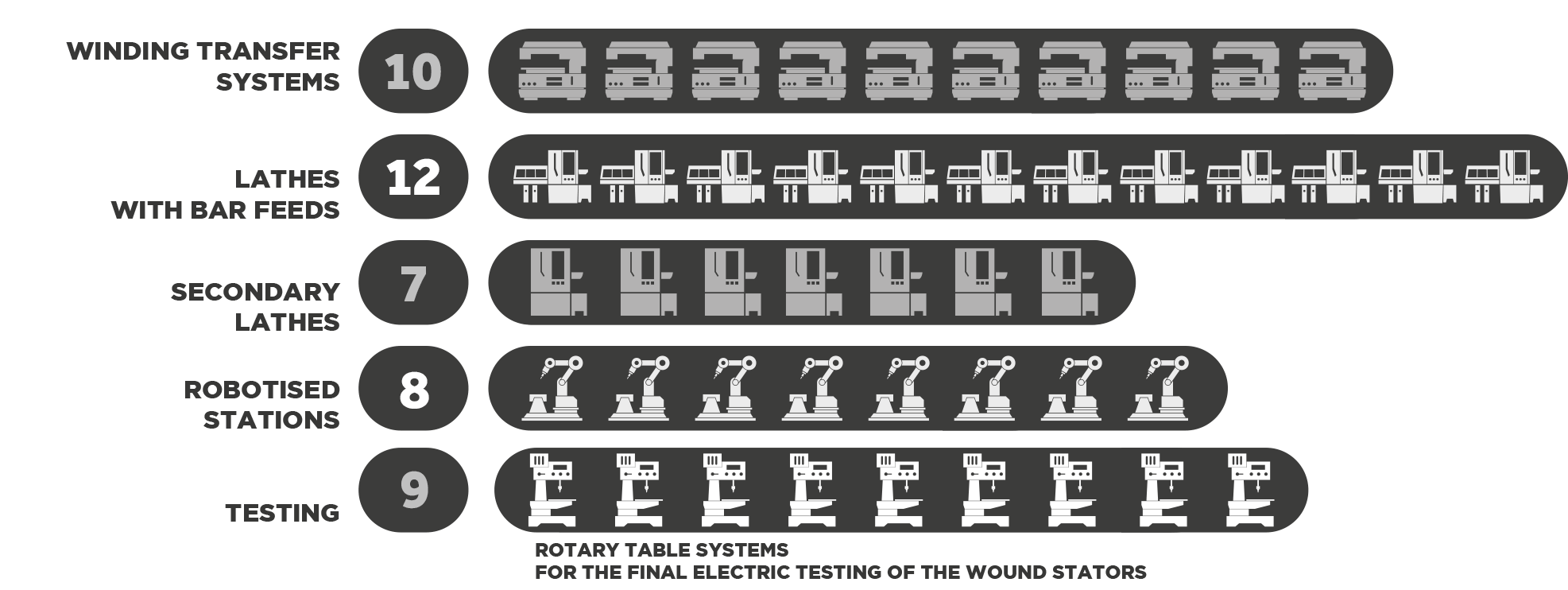

Systems

The market and the future

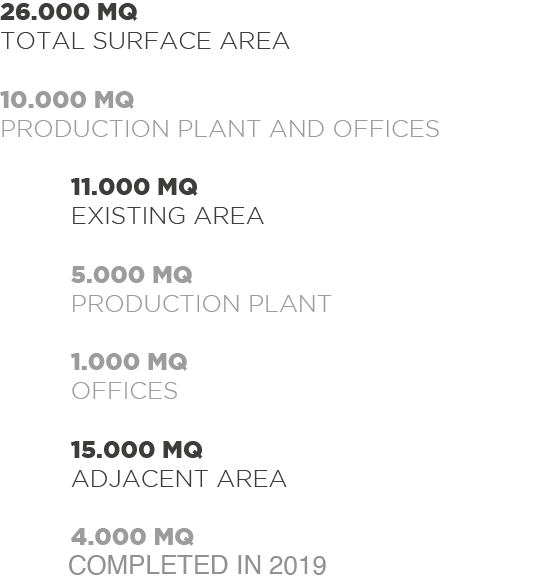

We continue to grow in terms of production, resources and turnover. In 2017 we produced 2 million and 500 thousand pieces.

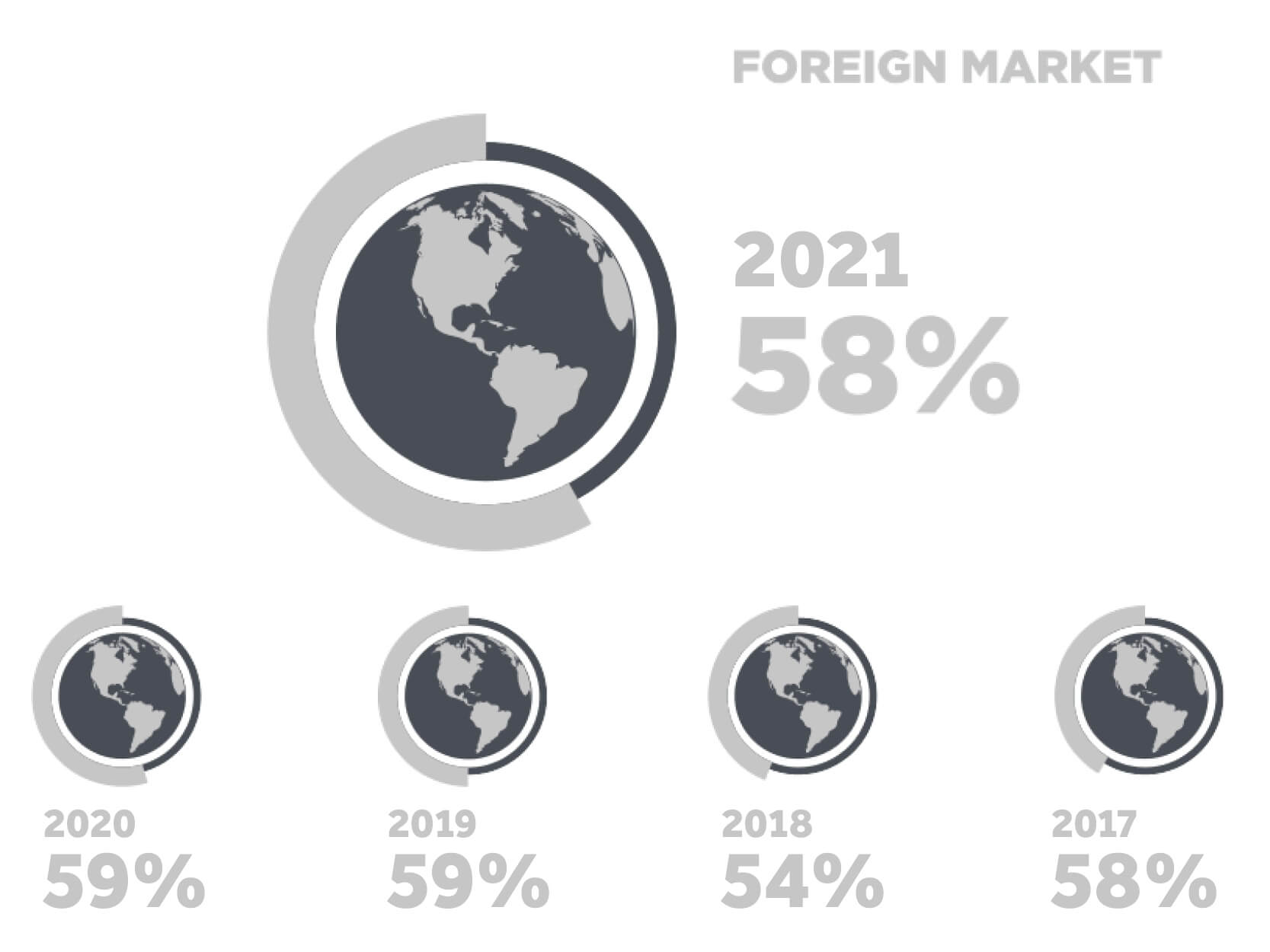

Over the years we have attracted the interest of new clients, international ones especially, and we have continued to invest in next generation production plants and in qualified personnel, so much so that over 58% of our turnover comes from the foreign market. The remaining 42% is Italian.

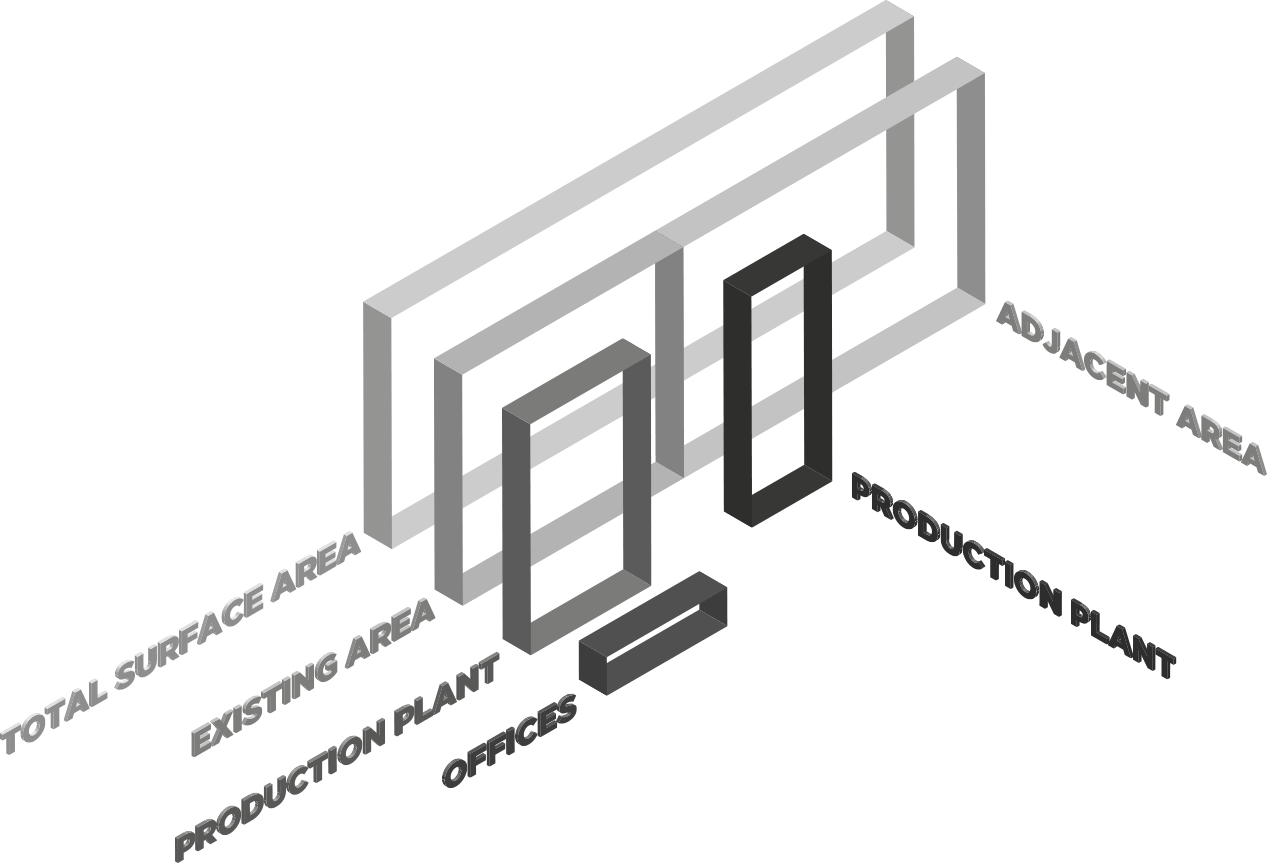

To address our latest production needs, we have planned the construction of another plant next to the existing one in Verolanuova. The new structure, under construction in the year 2018, shall cover a surface area of 4,000 m2 and shall be fitted with other state-of-the-art machinery.