EL-MI S.r.l.u. – Electric motors construction

EL-MI S.r.l.u – ELECTRIC MOTORS CONSTRUCTION

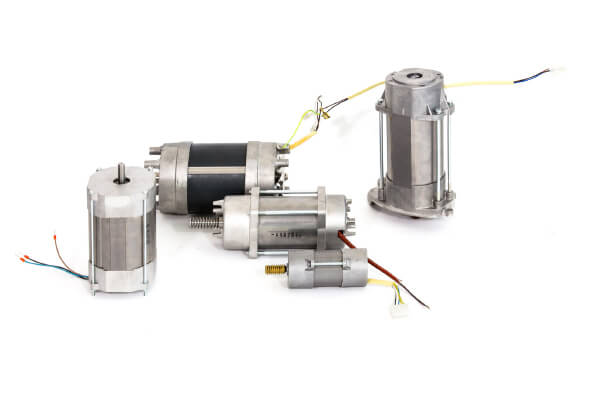

We produce special asynchronous motors with power output up to 1000 W.

We build complete electric motors, wound stators and machined rotors with design shaft, made to client specification. We are leaders in Europe in the production of electric motors for automatic opening systems.

For over 50 years we have been operating in the province of Brescia from our headquarters in Verolanuova. The company plant has a surface area of over 11,000 m2 that are currently being expanded to 26,000 with the ongoing renovation.

Thanks to our advanced technology systems, a very high specialisation level and the continuous training of our technical personnel, we are capable of meeting the most demanding requirements with great flexibility. Our elevated quality standards have allowed us to expand our national and international clientele.

We produce special asynchronous motors with power output up to 1000 W.

We build complete electric motors, wound stators and machined rotors with design shaft, made to client specification. We are leaders in Europe in the production of electric motors for automatic opening systems.

For over 50 years we have been operating in the province of Brescia from our headquarters in Verolanuova. The company plant has a surface area of over 11,000 m2 that are currently being expanded to 26,000 with the ongoing renovation.

OUR PRODUCTS

100% made in Italy

Since our company’s establishment, we produce entirely in Italy. Our choice has been to invest in our country and in our internal resources by highly automating our production departments, without outsourcing any part of our production to foreign countries and by focusing on the high quality of our products.

Customised production

The complete electric motors, the wound stators and the machined rotors with shaft are produced and customised by our engineering department based on the specific needs and requirements of the client. We provide made to measure solutions for our entire range of products, with very short lead times.

Advanced technology

We own highly automated state-of-the-art production systems: 10 winding transfer systems for stator coils, 12 lathes with bar feeds, 7 secondary lathes, 8 robotised stations for mechanical processing and 9 rotary table systems for the final electric testing of the wound stators.

Know-how and reliability

After celebrating our 50th business anniversary in 2022, we continue to pursue ever greater objectives and we invest in increasingly leading-edge machinery, with the concomitant hiring of new personnel. We are also planning to build a new plant with a 4,000 m2 production floor next to the main plant.

100% MADE IN ITALY

Fin dalla data di fondazione, realizziamo i nostri prodotti interamente in Italia. Abbiamo scelto di investire nel paese e nelle risorse interne automatizzando fortemente i reparti produttivi, evitando di delocalizzare la produzione all’estero e puntando fortemente sulla qualità dei prodotti.

PRODUZIONE CUSTOMIZZATA

I motori elettrici completi, gli statori avvolti e i rotori lavorati con albero vengono realizzati e personalizzati dal nostro ufficio tecnico in base alle esigenze e specifiche necessità del cliente. Per tutta la nostra gamma di prodotti, forniamo soluzioni su misura e in tempi rapidi.

TECNOLOGIA AVANZATA

Possiamo contare su un processo produttivo all’avanguardia e fortemente automatizzato: disponiamo di 7 transfer di bobinatura per gli avvolgimenti degli statori, 11 torni da barra, 7 torni da ripresa, 7 isole robotizzate per le lavorazioni meccaniche e 9 sistemi a tavola rotante per il collaudo elettrico finale degli statori avvolti.

ESPERIENZA E AFFIDABILITÀ

Celebrati i 45 anni di attività nel 2017, continuiamo a porci obiettivi da raggiungere ed investiamo in macchinari sempre più all’avanguardia, assumendo anche nuovo personale. Abbiamo inoltre in programma la costruzione di un nuovo stabilimento produttivo di 4.000 metri quadri adiacente al principale.

100% MADE IN ITALY

Since our company’s establishment, we produce entirely in Italy. Our choice has been to invest in our country and in our internal resources by highly automating our production departments, without outsourcing any part of our production to foreign countries and by focusing on the high quality of our products.

CUSTOMISED PRODUCTION

The complete electric motors, the wound stators and the machined rotors with shaft are produced and customised by our engineering department based on the specific needs and requirements of the client. We provide made to measure solutions for our entire range of products, with very short lead times.

ADVANCED TECHNOLOGY

We own highly automated state-of-the-art production systems: 10 winding transfer systems for stator coils, 12 lathes with bar feeds, 7 secondary lathes, 8 robotised stations for mechanical processing and 9 rotary table systems for the final electric testing of the wound stators.

KNOW-HOW AND RELIABILITY

After celebrating our 50th business anniversary in 2022, we continue to pursue ever greater objectives and we invest in increasingly leading-edge machinery, with the concomitant hiring of new personnel. We are also planning to build a new plant with a 4,000 m2 production floor next to the main plant.